Industrial Flooring

Industrial Flooring Services

The Mark of Excellence

The Mark of Excellence

Orienteck offers a complete industrial concrete flooring services including fixing reinforcement, concrete pumping, laying and finishing concrete, high tolerance floors and surface hardeners, enabling you to benefit from over 10 years experience of industrial concrete flooring without having to employ operatives directly.

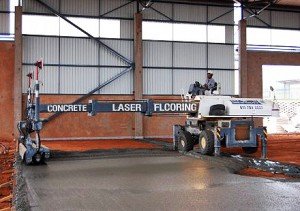

Laser Screed Flooring

Using the latest laser screed machinery, we can lay high tolerance concrete floor slab up to 2000 m2 in a single day. The tolerances achieved with our machine in free movement slabs are FM1, FM2 (special), FM2, and FM3 in accordance with the TR34 Document.

DM1, Category 1, & Category 2 that are required for high bay racking are achieved incorporating the laser screed large pour methods in defined movement slabs.

Where large pours are to be carried out to a tight tolerance, big laser screed flooring machines are definitely the machines to use, however if a small area of floor is to be laid to a tight tolerance, then we are able to lay this with our smaller laser screeds and power rakes that we have. This gives you a high tolerance concrete floor where the large laser screed cannot be used.

Hand lay Method

We have highly skilled operatives that can manually lay concrete slabs by hand, screeding to achieve high tolerances such as FM2 (special) or FM2. We can also provide cat 1 and super flat floors laying by hand depending on the width of the bays.

We have highly skilled operatives that can manually lay concrete slabs by hand, screeding to achieve high tolerances such as FM2 (special) or FM2. We can also provide cat 1 and super flat floors laying by hand depending on the width of the bays.

As well as being able to achieve the tolerances stated above, we can also hand lay large areas to falls, which is common in external yard areas and also internal concrete slabs where drains have been installed to take away liquids.

Laying the floors in this method enables us to lay and finish 1000m² of concrete slab in one day, whether it is ground floors, upper floors, and external yard slabs.

Also where we are unable to use the laser screeds due to the method of construction, we can still achieve a high tolerance floor slab using this hand lay method.

Power Float Concrete

Power float concrete results in a hardwearing finished surface, suitable for high trafficked areas both foot and forklift dependent on depth. Power float machines are fitted with circular pans to help smooth the concrete before metal blades are rotated over the surface adjusting the tilt to achieve a hardened surface.

Before the concrete can be power floated, it has to be left to harden, so a concrete installed in the morning cannot usually be power floated until late afternoon depending on the mix and outside conditions. Power-floating produces a flat smooth dense finish. Min depths are 75mm bonded, 100mm un-bonded for foot traffic and designed between 150mm – 350mm dependant on loadings for trafficked areas. Drying times for foot traffic are 24 hours, the concrete dries at approximately 1mm per day and should not be force dried. These types of floors can be reinforced with Mesh, plastic or steel fibers, depending on use and loadings.

Hand Trawled finish

Easy-float concrete results in a hardwearing finished surface, suitable for computer floors, Carpet floors or tiled areas. Concrete is laid and leveled either via pump or discharged of the back of the wagon and when the concrete has been leveled by tamp, the concrete is hand floated with an Easy-float to give a smooth finish. Whilst this finish is not as smooth as power floated, it is still suitable for carpet, screed or tiles.

Min depths are 75mm bonded, 100mm un-bonded for foot traffic and designed between 150mm – 350mm depending on loadings for trafficked areas. Drying times for foot traffic are 24 hours, the concrete dries at approximately 1mm per day and should not be force dried. These types of floors can be reinforced with Mesh, plastic or steel fibers, dependant on use and loadings.

Dry Shake toppings

Where required we can also spread a dry shake surface topping to any floor slab that we install. This can be for a number of reasons such as color of concrete for aesthetic reasons, surface hardening or to help achieve certain abrasion resistance requirements such as AR special or AR1.

The dosage of the dry shake is usually depends on the design and end use of the floor slab, but we can apply this topping in two ways:

– Spreading the topping by hand

– Spreading the topping using a pedestrian tremex spreader

All of the above techniques enable us to spread the required dosage (kg/m²) on to the slab. Due to our professional relationships with various dry shake topping manufacturers, we are able to tailor the material application to the clients requirements, and usually attend site pre-start meetings with these suppliers to ensure both client and supplier are 100% happy with the installation of the slab and topping.

Epoxy Based Industrial Floor coverings

Produces and recommends systems based on projects with regards to specific dye and covering production for the companies involved in heavy services and industrial production. Epoxy Floor Covering Systems finds a broad area of application in every sector active in industrial production in particular, food, textile, petro chemistry. The floor coverings being a factor that directly affects the production quality in factories of heavy industry and industrial production, they increase the quality of production and provide a long term mechanical and chemical resistance.

Epoxy floor coverings which find an area of application especially in the textile, food and hospitals where dust emission is unwanted or in factory

Epoxy floor coverings which find an area of application especially in the textile, food and hospitals where dust emission is unwanted or in factory

floors where heavy machinery and equipment and hardware are produce that require mechanical resistance or in the floors of dying plants, drug production facilities, petro chemistry facilities that are exposed to heavy chemical impacts provide the establishments with advantages of production performance, product quality, compliance with international standards and cost in medium and long term.

For more information about epoxy, please go to services – waterproofing – epoxy coverings.